Motion Control – Voice -Coil Stage

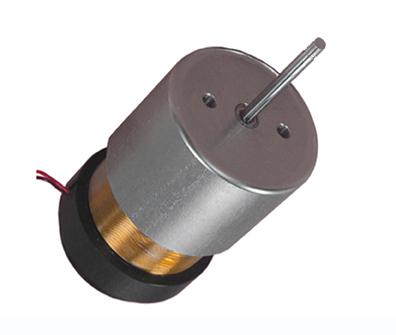

Van Nuys, CA – Motion Control – Components -– Moticont has released the miniature GVCM-016-019-01M Linear Voice Coil Servo Motor. Smaller in diameter than a US Dime this 15.9 mm (0.625 in.) diameter Servo motor, also called an Electric Cylinder, features a high force-to-size ratio of 1.5 N (5.3 oz) continuous force and 4.6 N (16.6 oz) of peak force.

February 16th, 2026

February 16th, 2026  Editor/Publisher

Editor/Publisher